METROM’s

Blog

METROM’s

Blog

Revolutionizing Manufacturing: The Essential Guide to CNC Machine Industrial Innovations

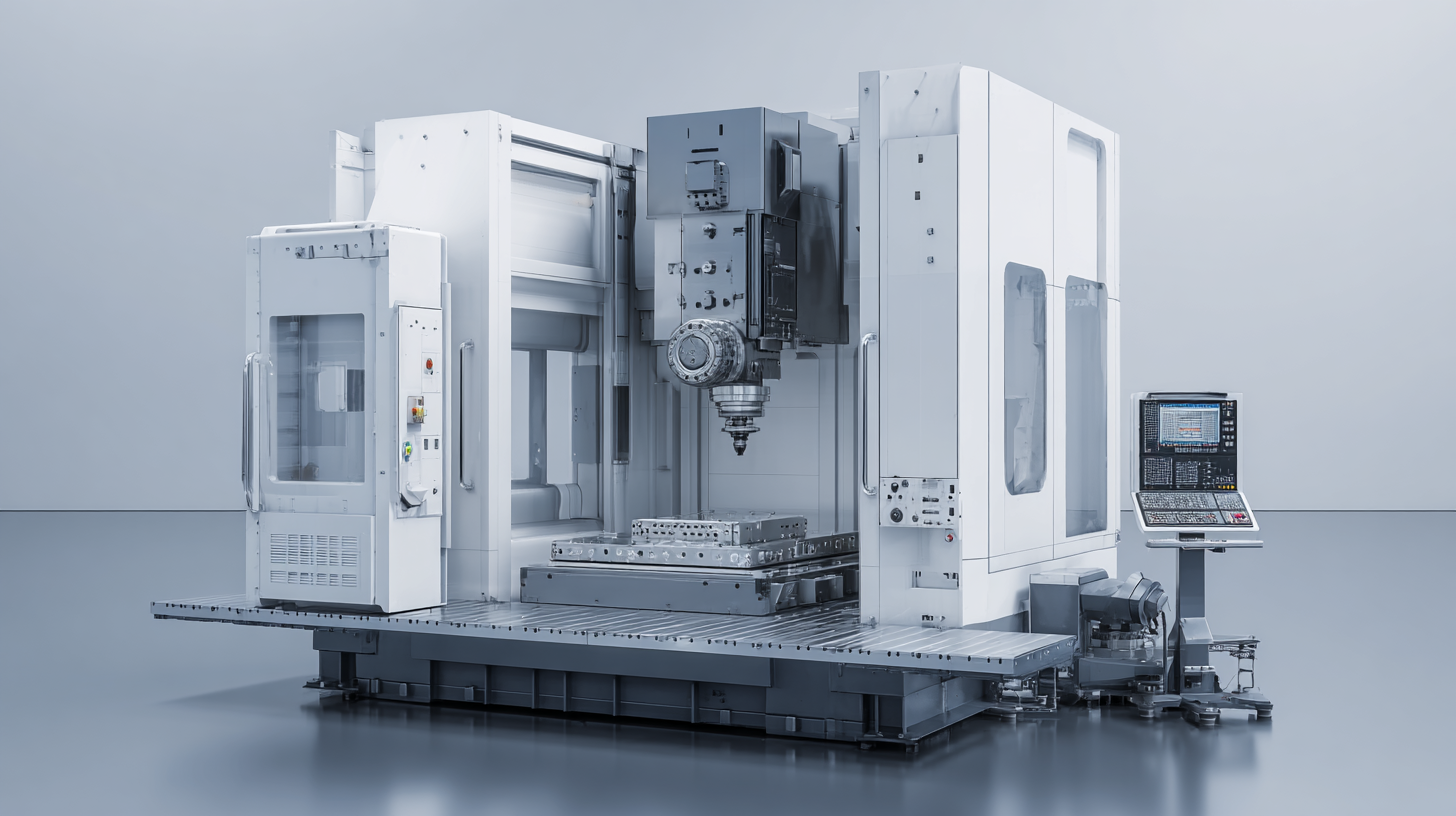

The manufacturing industry is undergoing a profound transformation fueled by the advent of CNC machine industrial technologies. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 117.2 billion by 2026, with a compound annual growth rate (CAGR) of 6.4% from 2021 to 2026. This remarkable growth underscores the pivotal role CNC machines play in enhancing production efficiency, precision, and flexibility within the manufacturing sector.

In the face of increasing demands for customization and rapid turnaround times, manufacturers are turning to CNC machine industrial innovations to streamline their processes. By automating tasks traditionally performed by human labor, CNC machines not only minimize human error but also significantly reduce production time, leading to heightened competitiveness in an increasingly global marketplace. A study from the National Institute of Standards and Technology highlights that businesses investing in advanced manufacturing technologies, including CNC machinery, can improve productivity by up to 30%, showcasing the critical impact of these innovations.

As we delve into the "Top 10" features and advancements in CNC machine industrial technologies, this guide aims to equip manufacturers and industry stakeholders with essential insights and information needed to navigate and capitalize on this evolving landscape. Embracing these innovations will not only enhance operational capabilities but also drive the future of manufacturing towards sustainability and greater economic resilience.

The Evolution of CNC Machining: A Historical Perspective on Industrial Innovations

The history of CNC (Computer Numerical Control) machining is a fascinating journey that showcases the remarkable evolution of industrial innovations. Starting from the early days in the 1940s, when numerical control was introduced using punched tapes, CNC technology has fundamentally transformed the manufacturing landscape. According to a report by the Research and Markets, the global CNC machine market is expected to reach $121 billion by 2027, growing at a CAGR of 6.3% from 2020. This growth underscores how CNC machining has become integral to efficient manufacturing processes.

The evolution of CNC machining has been marked by continuous technological advancements, transitioning from basic control systems to highly sophisticated software that integrates Artificial Intelligence and IoT capabilities. In recent years, the integration of 5-axis machining has further revolutionized the industry, allowing for more complex and precise manufacturing. A report by MarketsandMarkets indicates that the 5-axis CNC market alone is projected to grow from $1.97 billion in 2020 to $3.23 billion by 2025, reflecting the increasing demand for precision engineering. As CNC machines continue to evolve, the enhancements in automation and efficiency signify a new era in manufacturing that is reshaping production capabilities across various industries.

Revolutionizing Manufacturing: The Essential Guide to CNC Machine Industrial Innovations

| Innovation Year | Innovation Type | Description | Impact on Industry |

|---|---|---|---|

| 1940s | Numerical Control (NC) | Introduction of NC machines that used punched tape for automation. | Increased precision and reduced labor costs. |

| 1960s | Computer Numerical Control (CNC) | Development of CNC machines with programmable computers. | Enabled complex operations and improved manufacturing flexibility. |

| 1980s | CAD/CAM Integration | Integration of computer-aided design and computer-aided manufacturing. | Streamlined processes and reduced time from design to production. |

| 2000s | Additive Manufacturing | Adoption of 3D printing technologies in CNC machining. | Revolutionized prototyping and customization capabilities. |

| 2020s | Smart CNC Machines | Implementation of IoT and AI in CNC operations. | Enhanced monitoring, predictive maintenance, and efficiency. |

Key Innovations Transforming CNC Technology in Modern Manufacturing

The modern manufacturing landscape has experienced transformative changes due to key innovations in CNC (Computer Numerical Control) technology. The integration of advanced digital manufacturing technologies has resulted in heightened productivity across various industries. CNC machines now utilize sophisticated software and intricate algorithms that enhance precision and efficiency, enabling manufacturers to optimize their production processes significantly. This shift not only reduces operational costs but also accelerates the time-to-market for new products.

Nanotechnology plays a crucial role in this transformation, as it enables the development of novel materials with enhanced properties. By manipulating materials at the nanoscale, manufacturers can create components that are lighter, stronger, and more resistant to wear, thus driving innovation in product design and functionality. Furthermore, the embrace of artificial intelligence and robotics is ushering in a new era for machining. These technologies not only streamline operations but also facilitate smarter decision-making, enabling industries to adapt quickly to changing market demands and improving overall competitiveness. The convergence of these advancements is revolutionizing the CNC industry, setting a new standard for manufacturing excellence.

Enhancing Precision: The Role of Advanced Sensors in CNC Machines

The integration of advanced sensors in CNC machines is revolutionizing the manufacturing process by significantly enhancing precision and efficiency. These sensors allow for real-time monitoring and adjustments, ensuring that each component is machined to exact specifications. This capability is crucial as industries demand higher standards of quality, which is reflected in the projected growth of the CNC machine market, expected to reach $195.59 billion by 2032. The role of these sophisticated sensors cannot be overstated; they facilitate faster production cycles and reduce waste, aligning with the industry's move toward more sustainable practices.

The integration of advanced sensors in CNC machines is revolutionizing the manufacturing process by significantly enhancing precision and efficiency. These sensors allow for real-time monitoring and adjustments, ensuring that each component is machined to exact specifications. This capability is crucial as industries demand higher standards of quality, which is reflected in the projected growth of the CNC machine market, expected to reach $195.59 billion by 2032. The role of these sophisticated sensors cannot be overstated; they facilitate faster production cycles and reduce waste, aligning with the industry's move toward more sustainable practices.

Tips: To maximize the benefits of advanced sensors, manufacturers should invest in regular training for their operators. Understanding how to interpret sensor data and respond swiftly to alerts can drastically improve overall machine performance. Additionally, monitoring the calibration and maintenance of sensors is essential to maintain precision over time. Regular audits of sensor functionality will help catch potential issues before they escalate, ensuring consistent quality in production.

As innovations in nanotechnology emerge, their impact on CNC machining also cannot be ignored. These advancements are paving the way for even finer tolerances and enhancing material properties, contributing to a more robust manufacturing environment. Manufacturers should remain at the forefront by continuously exploring new technologies that can be integrated into their CNC operations, ensuring they remain competitive in a rapidly evolving market.

The Impact of Automation and AI on CNC Machine Efficiency

The CNC machine market is experiencing groundbreaking changes, primarily driven by advancements in automation and AI. These technologies are enhancing efficiency, allowing for improved precision in processes such as cutting, shaping, and drilling various materials. The digital transformation in manufacturing is not merely a trend; it represents a critical shift towards higher productivity and lower operational costs. The CNC market is projected to see significant growth, with forecasts indicating the market will expand from $5.2 billion in 2022 to an estimated $8.8 billion by 2030, reflecting a compound annual growth rate of 7.2%.

**Tip:** To optimize your CNC operations, consider investing in AI-driven software that can analyze production data in real-time, thereby reducing downtime and increasing output efficiency.

As the industry evolves, the importance of integrating smart technologies cannot be overstated. CNC machines equipped with advanced automation capabilities can seamlessly transition from routine tasks to complex operations with minimal human intervention. This shift not only augments production capabilities but also opens doors for innovative applications across various sectors, setting the stage for a revolutionary leap in manufacturing processes.

**Tip:** Regular maintenance and updates for CNC systems are crucial. Keeping software and hardware up-to-date ensures you leverage the latest advancements in technology for peak performance and reliability.

Impact of Automation and AI on CNC Machine Efficiency

Sustainable Practices in CNC Manufacturing: Innovations for a Greener Future

On May 14, the Dr. D. Y. Patil Institute of Technology in Pimpri, Pune, made headlines by hosting an influential conference focused on sustainable practices in CNC manufacturing. This gathering brought together industry leaders and innovators to discuss the critical role that CNC technology plays in driving environmentally friendly manufacturing solutions. Attendees highlighted the importance of integrating sustainable materials and processes to reduce waste and energy consumption, emphasizing the need for a greener future in the manufacturing sector.

The discussions centered around the latest advancements in CNC machine technologies that not only enhance productivity but also promote sustainability. Innovations such as energy-efficient machinery, biodegradable materials, and advanced recycling techniques were showcased as essential components in transforming traditional manufacturing practices. With a strong commitment to minimizing environmental impact, the conference served as a platform for collaboration, inspiring participants to explore cutting-edge solutions that align with global sustainability goals.

Related Posts

-

How to Choose the Right Axis CNC Machine for Your Business Needs

-

The Ultimate Guide to CNC Machine Tools Understanding Trends Technologies and Market Dynamics

-

The Future of CNC Machines: Revolutionizing Global Manufacturing and Precision Engineering

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

-

Crafting Excellence in CNC Machining for Global Manufacturing Solutions