METROM’s

Blog

METROM’s

Blog

Unmatched Precision and Innovation Chinese Manufacturing Leads the Way in High Precision Milling Machines

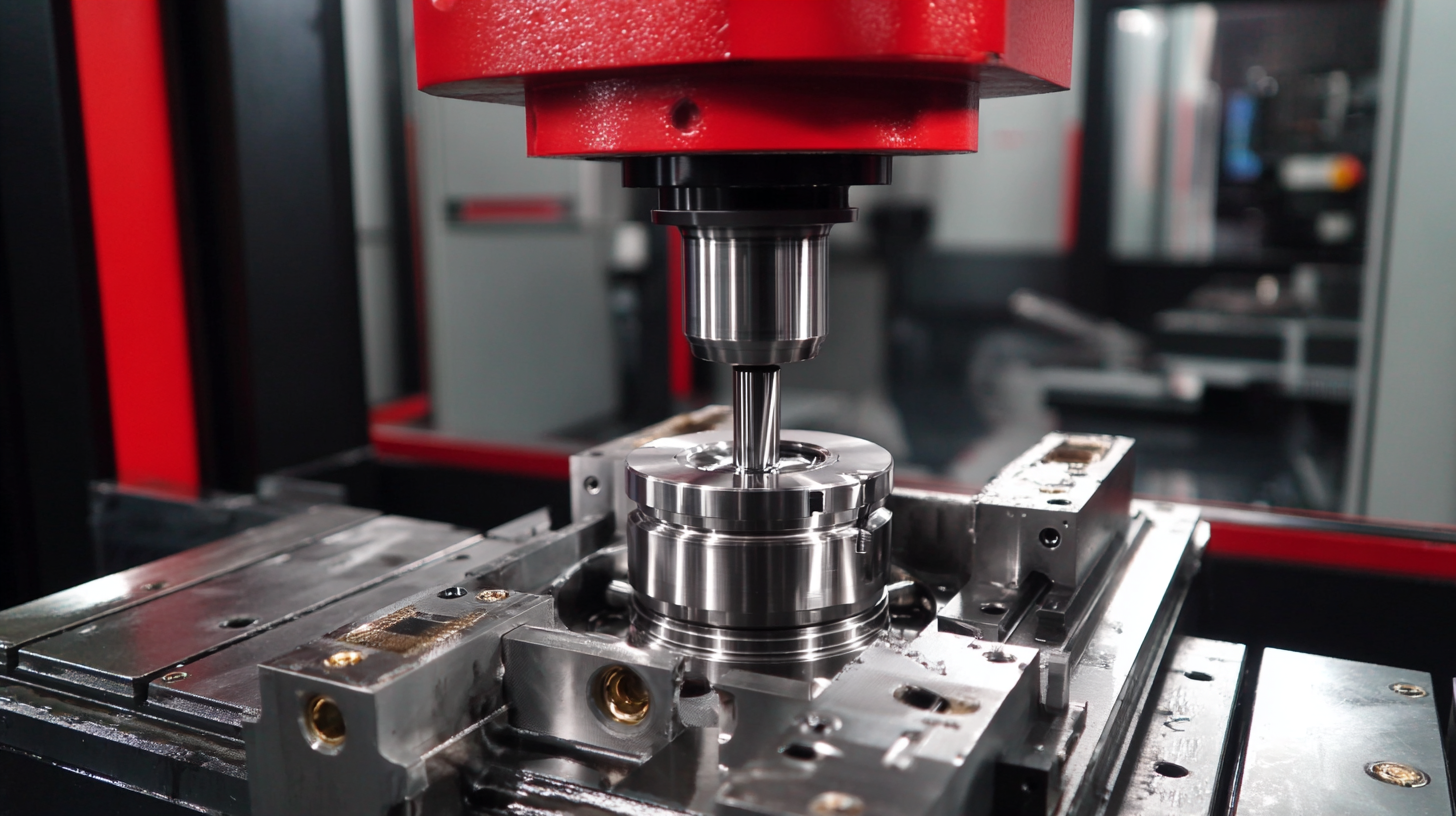

In recent years, the global manufacturing landscape has been significantly impacted by the advancements in high precision milling machines, with Chinese manufacturers leading the charge in innovation and precision engineering. According to a report by MarketsandMarkets, the global precision machining market is expected to reach $104.8 billion by 2025, driven largely by the increasing demand for high-precision components across industries such as aerospace, automotive, and electronics.

Chinese companies are at the forefront of this revolution, leveraging cutting-edge technology and automated processes to enhance production efficiency and accuracy. With their ability to produce high precision milling machines that meet stringent international standards, they are not only gaining market share but also setting new benchmarks for quality and performance in the global arena.

Unveiling the Technical Specifications of High Precision Milling Machines

Chinese manufacturing has emerged as a global leader in the production of high precision milling machines, characterized by cutting-edge technology and innovative design. These machines boast remarkable technical specifications that enhance productivity and accuracy in industrial applications. High precision milling machines from China typically integrate advanced CNC (Computer Numerical Control) systems, enabling operators to achieve intricate designs with exceptional repeatability. Features such as spindle speeds exceeding 20,000 RPM and robust linear guides further highlight their precision capabilities, making them ideal for complex machined parts across various sectors.

Tips for selecting the right high precision milling machine:

- Assess your specific machining needs in terms of material type and part complexity.

- Consider the machine's torque and power ratings, which significantly influence performance during demanding tasks.

- Evaluate the availability of support services and spare parts from the manufacturer, as having reliable maintenance options is key to ensuring long-term operational efficiency.

By understanding these specifications and tips, businesses can make informed decisions that enhance their manufacturing processes and drive innovation forward.

Key Innovations from Chinese Manufacturers in the Milling Industry

Chinese manufacturers have made significant strides in the milling industry, showcasing key innovations that are reshaping the landscape of high precision milling machines. One notable advancement is the integration of advanced automation technology, which enhances production efficiency and accuracy. By utilizing robotics and AI-driven systems, these manufacturers can streamline operations, reduce human error, and maximize output while maintaining stringent quality control. This level of sophistication not only boosts productivity but also allows for more intricate designs that were previously unattainable.

In addition to automation, Chinese manufacturers are investing heavily in research and development to refine the materials used in milling machines. The introduction of high-performance alloys and cutting-edge coatings has significantly improved the durability and lifespan of machine components. This innovation enables milling machines to operate at higher speeds and temperatures without compromising precision. Furthermore, Chinese firms are also focusing on environmentally friendly practices, implementing sustainable manufacturing processes that reduce waste and energy consumption. These efforts position China's milling industry at the forefront of global manufacturing, setting new standards for precision and innovation.

Unmatched Precision: Innovations in Chinese High Precision Milling Machines

This chart illustrates the percentage of key innovations adopted by Chinese manufacturers in the high precision milling machines sector. The data reflects the trends and advancements in technology that have propelled the Chinese milling industry to the forefront of global manufacturing.

Comparative Analysis: Chinese Precision Milling Machines vs. Global Competitors

The landscape of the machine tools market is evolving, with Chinese precision milling machines at the forefront of innovation and performance. As the global demand for high-quality machining solutions rises, China capitalizes on this trend by developing advanced milling technologies that compete effectively with traditional manufacturing powerhouses. The focus on precision in machining processes has propelled Chinese manufacturers to enhance their capabilities, integrating cutting-edge techniques and sophisticated designs.

In comparative analyses, Chinese milling machines demonstrate significant advantages in both cost-effectiveness and technological advancements. As the market is projected to grow substantially, with an increase from USD 81.09 billion in 2025 to USD 105.11 billion by 2030, the efficiency and reliability of these machines attract attention from industries requiring high precision and productivity. The rise of the Chinese manufacturing sector signifies a shift in the global machine tools landscape, where innovation and rapid development continue to drive competition and set new benchmarks for quality and performance.

Step-by-Step Guide: Selecting the Right High Precision Milling Machine

When selecting the right high precision milling machine, it is crucial to first consider the specific needs of your production processes. According to a report by Grand View Research, the global market for precision machining is projected to reach $10.26 billion by 2025, indicative of an increasing demand for highly accurate machining tools. Buyers should evaluate their requirements by assessing factors such as the materials to be machined, desired dimensional tolerances, and production volume. High precision milling machines are designed to meet these diverse needs, providing the flexibility required for both large-scale and small-batch production.

Next, potential users should examine the technological capabilities of available milling machines. A study from Technavio highlights that the adoption of advanced technologies such as CNC (Computer Numerical Control) is elevating the performance standards in the milling industry, offering improvements in precision and speed. Technologies like real-time monitoring can enhance accuracy and reduce downtime, making it essential to choose a machine equipped with such features. Additionally, considering the machine’s compatibility with CAD/CAM software can also streamline operations, increasing overall efficiency and productivity in manufacturing settings.

Unmatched Precision and Innovation: High Precision Milling Machines Comparison

| Model | Precision (μm) | Maximum Spindle Speed (RPM) | Worktable Size (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 5 | 12000 | 600x400 | 1500 | 45000 |

| Model B | 3 | 10000 | 800x500 | 2000 | 55000 |

| Model C | 4 | 15000 | 700x400 | 1700 | 60000 |

| Model D | 2 | 18000 | 900x600 | 2500 | 70000 |

Future Trends in Chinese Manufacturing of Precision Milling Equipment

The landscape of precision milling equipment manufacturing in China is evolving rapidly, driven by advancements in technology and increased domestic demand. According to the 2024 research report on China's machine tool industry, the market for general machine tools, including milling machines, is widespread across various mechanical processing fields. While these machines meet standard precision requirements, the growing appetite for high-end CNC (computer numerical control) machines is rising. In fact, the Chinese market for CNC machines reached 409 billion yuan in 2023, with an expected growth to 432.5 billion yuan by 2024, reflecting a compound annual growth rate of 5.75% from 2019 to 2023.

Additionally, China is witnessing a surge in precision processing technologies, particularly in laser processing equipment manufacturing. The market size for this sector is projected to reach approximately 89.9 billion yuan in 2024. The ongoing push for localization in manufacturing and an increase in export capacity highlight the country's transition toward becoming a global leader in high-tech manufacturing. The rising adoption of five-axis milling machines among manufacturers signifies the shift towards higher precision and more complex machining capabilities, aligning with future trends that prioritize innovation and technological advancement in Chinese manufacturing.