METROM’s

Blog

METROM’s

Blog

Unlocking Precision: A Beginner's Guide to Advanced Milling Machine Tools for Enthusiasts

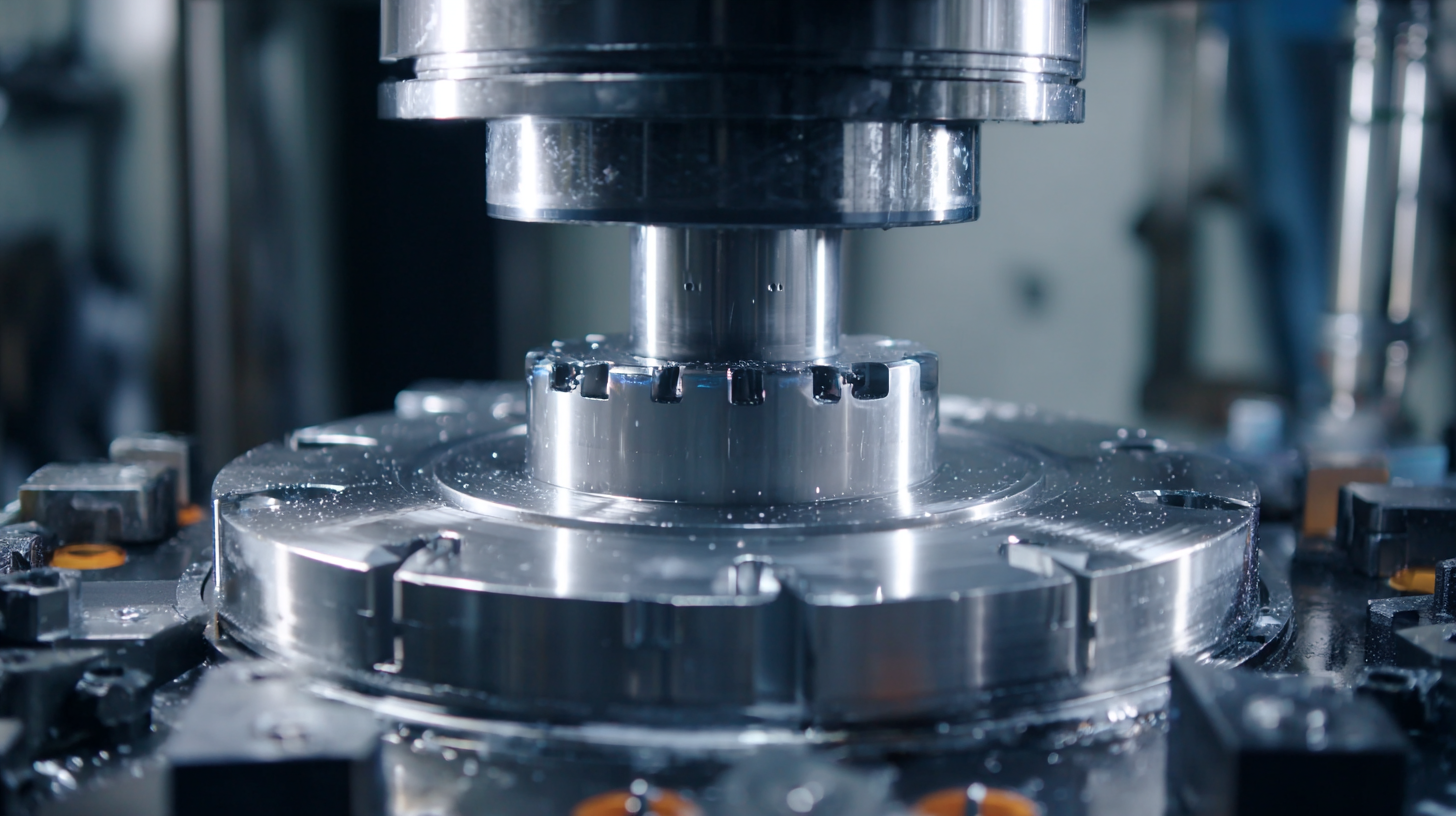

In recent years, the demand for precision manufacturing has surged, leading to an increased interest in advanced milling machine tools among enthusiasts and professionals alike. According to a report by MarketsandMarkets, the global CNC milling machine market is projected to reach $60 billion by 2025, highlighting the pivotal role that these tools play in modern manufacturing processes. Milling machine tools are not only essential for achieving intricate designs and high tolerances but also for enhancing productivity and efficiency.

As technology continues to evolve, beginner enthusiasts are now presented with a myriad of options that can cater to both their creative pursuits and technical requirements. Understanding the various types and capabilities of milling machine tools is key to unlocking precision in any machining project, paving the way for innovative applications across multiple industries.

Understanding the Basics of Milling Machines for Beginners

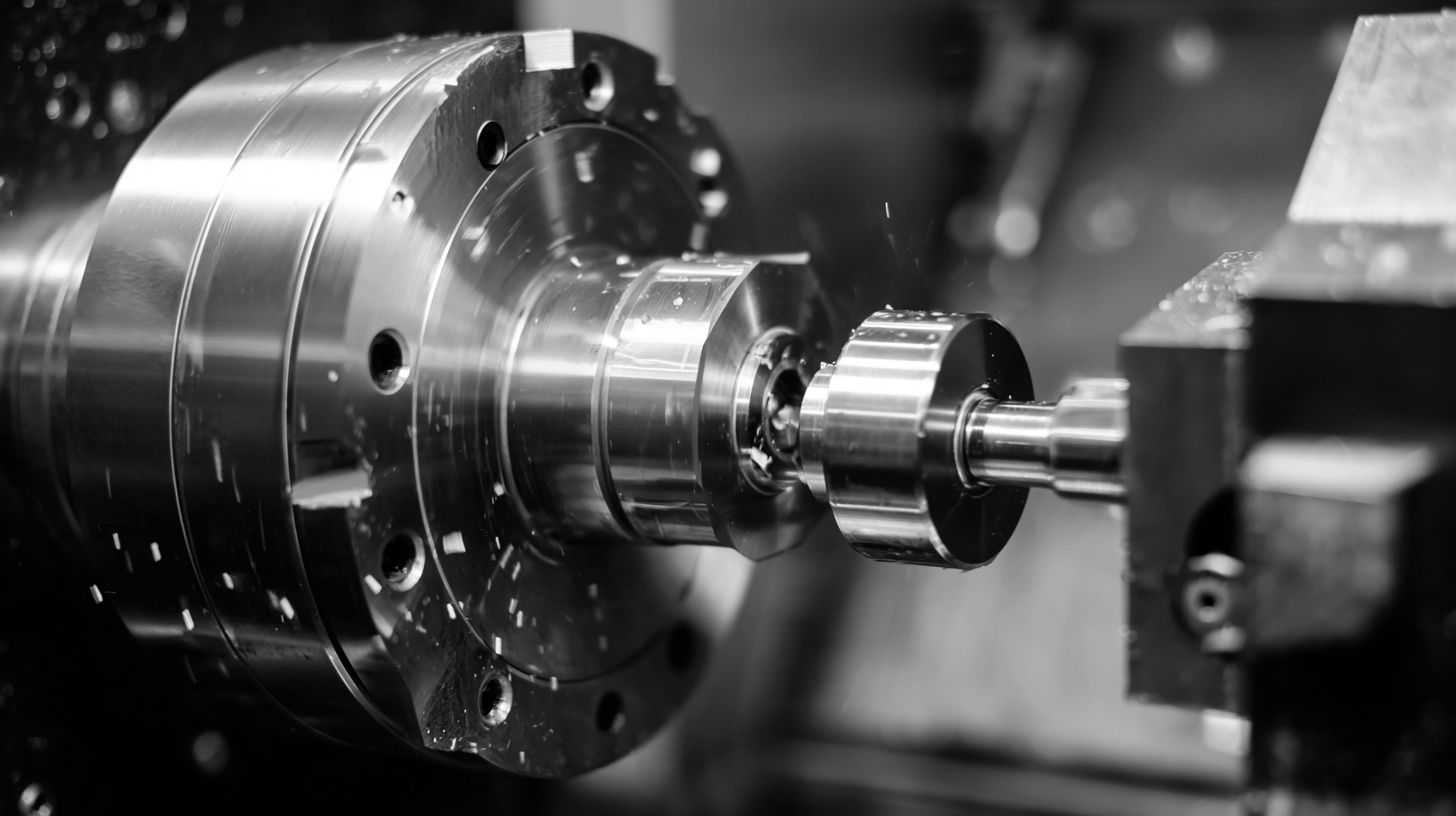

Milling machines are essential tools in the world of machining, providing

precision and versatility for both beginners and enthusiasts alike.

Understanding the basics of these machines is crucial for anyone looking to delve into the field.

A milling machine can perform various operations, such as cutting, drilling, and shaping materials, allowing

users to create complex parts with exact specifications. Familiarizing oneself with different

types of milling machines—such as vertical and horizontal—can enhance one’s ability to choose the right tool

for a specific project.

Milling machines are essential tools in the world of machining, providing

precision and versatility for both beginners and enthusiasts alike.

Understanding the basics of these machines is crucial for anyone looking to delve into the field.

A milling machine can perform various operations, such as cutting, drilling, and shaping materials, allowing

users to create complex parts with exact specifications. Familiarizing oneself with different

types of milling machines—such as vertical and horizontal—can enhance one’s ability to choose the right tool

for a specific project.

Tips: Start by learning about the various components of a milling machine,

including the spindle, table, and tool holder. Understanding how these parts work together will give you a solid

foundation for operating the machine. Additionally, always observe proper safety protocols and operating

procedures to mitigate risks while enhancing your machining skills.

As you advance, explore how post processors function within milling software. They bridge the gap between

the computer-aided design (CAD) models and the actual machine operation, optimizing

how the milling tasks are executed. Knowing how to customize post processors can significantly improve your workflow,

ensuring that your designs are translated accurately into the completed product.

Essential Components of Advanced Milling Tools You Need to Know

When exploring advanced milling machine tools, understanding the essential components is crucial for enthusiasts aiming to enhance their precision machining skills. Key elements include the spindle, which plays a significant role in determining the cutting speed and overall efficiency of the milling process. According to a report by the International Association of Machinists, machines equipped with high-quality spindles can increase productivity by over 30%. Additionally, tool holders and inserts are vital; they must be compatible with the machine's specifications to ensure optimal performance and tool longevity.

Tips: Always choose tooling that matches the material you are working with. For instance, carbide inserts excel in machining harder materials due to their durability and heat resistance, as highlighted in a study by the Society of Manufacturing Engineers, which found that using the correct inserts can reduce tooling costs by up to 25%.

Another critical component is the coolant system, which helps maintain cutting temperature and prolongs tool life. Effective cooling leads to improved surface finish and dimensional accuracy. Research from the American Society of Mechanical Engineers indicates that milling operations with efficient coolant management can achieve up to a 40% increase in tool lifespan.

Enhancing your understanding of these components not only boosts your confidence but also significantly impacts the quality and efficiency of your projects.

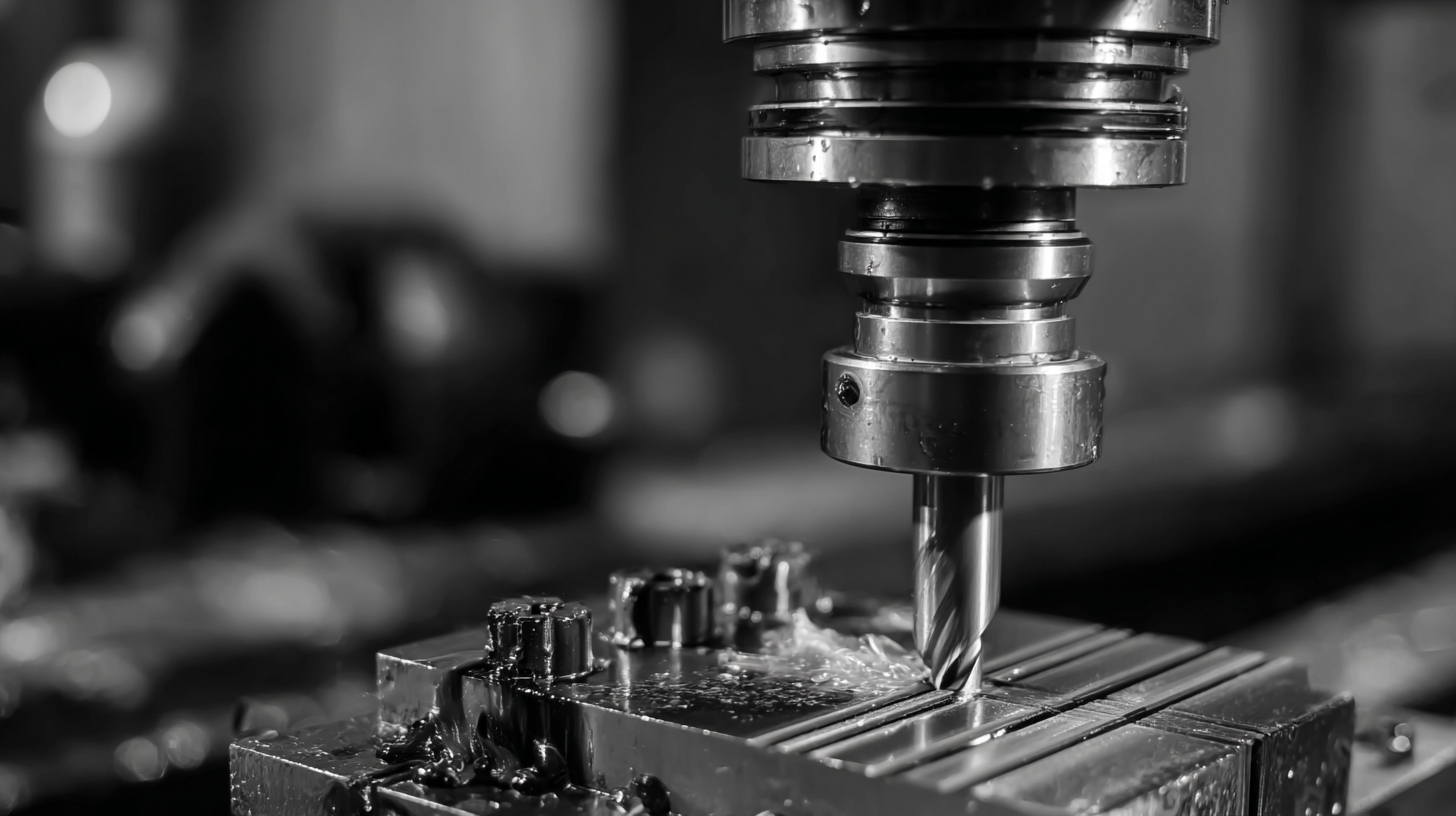

Key Techniques for Operating Milling Machines Like a Pro

Operating a milling machine like a pro requires a solid understanding of key techniques that enhance both precision and efficiency. First, mastering the setup process is crucial. This includes securely fastening the workpiece and correctly aligning the cutting tool. Using tools such as dial indicators and edge finders, enthusiasts can ensure that the milling machine operates within the desired tolerances. Additionally, selecting the right feed rate and spindle speed is vital, as these variables can significantly affect the quality of the finish and the lifespan of the cutting tools.

Another technique that elevates milling operations is understanding the different milling methods, such as climb milling and conventional milling. Each method has its own advantages and disadvantages; for instance, climb milling typically yields a better surface finish while conventional milling is often more forgiving with rough materials. Moreover, familiarizing oneself with tool geometry and selection greatly influences the efficiency of milling processes. By exploring various cutting tools and their applications, enthusiasts can navigate complex projects with confidence, achieving professional results in their milling endeavors.

Safety Practices and Maintenance Tips for Your Milling Equipment

Safety practices and maintenance tips are critical components for anyone utilizing advanced milling machine tools, especially for hobbyists and enthusiasts. Recent discussions around workplace safety in various industries highlight the importance of these practices. For example, new guidelines aimed at reducing airborne silica in asphalt milling represent a decade of research and emphasize the need for safer operational standards. Applying these principles, milling equipment operators can significantly improve their safety practices, ensuring a lower risk of accidents and health issues.

Understanding essential maintenance strategies plays a key role in maximizing the lifespan and operational efficiency of milling equipment. Evidence indicates that proactive maintenance can reduce equipment downtime by up to 20%, significantly impacting productivity. For example, in mining operations, effective maintenance strategies for gearless mill drives are crucial, potentially extending equipment life and minimizing costly interruptions. Adopting a routine maintenance schedule that incorporates safety checks can lead to a more efficient and safer work environment, underscoring the connection between responsible equipment use and overall workplace safety.

Tool Wear Comparison in Advanced Milling Operations

Exploring Projects: Creative Applications of Advanced Milling Techniques

In recent years, advanced milling techniques have opened new doors for both hobbyists and professionals looking to push the boundaries of creativity in manufacturing and crafting. With the rise of precision milling machines, enthusiasts can now explore intricate projects that were once the realm of industrial experts. Reports suggest that the global market for milling machines is projected to reach approximately $100 billion by 2027, driven by innovations in automation and CNC technology. This surge in popularity reflects a growing enthusiasm among makers to experiment with different materials and techniques, leading to unique applications in areas such as art, design, and even jewelry making.

As nations like China enhance their innovation capabilities, the implications for the milling industry are profound. The advancement of domestic companies and universities in China is leading to a wave of new techniques that are directly influencing global trends. For instance, techniques discovered in Colombia's mineral exploration offer insights into how precision milling can unearth hidden potential, creating novel opportunities for product development. Enthusiasts can draw inspiration from these advancements to tackle their own creative projects, whether it's crafting custom components for robotics or creating intricate designs for fine jewelry, exemplifying the fusion of traditional craftsmanship with modern technology.

Related Posts

-

Strategies for Sourcing the Best Milling Machine Tools in the Market Analysis of 2025

-

China Craftsmanship in Milling Machines Elevating Global Standards and Sales Success

-

Exploring the Best CNC Machines and Their Alternatives for Your Business Needs

-

Top Strategies for Choosing the Best CNC Machine Tools for Your Business

-

The Ultimate Guide to CNC Machine Tools Understanding Trends Technologies and Market Dynamics

-

7 Best CNC Machine Innovations Transforming Manufacturing in 2023