METROM’s

Blog

METROM’s

Blog

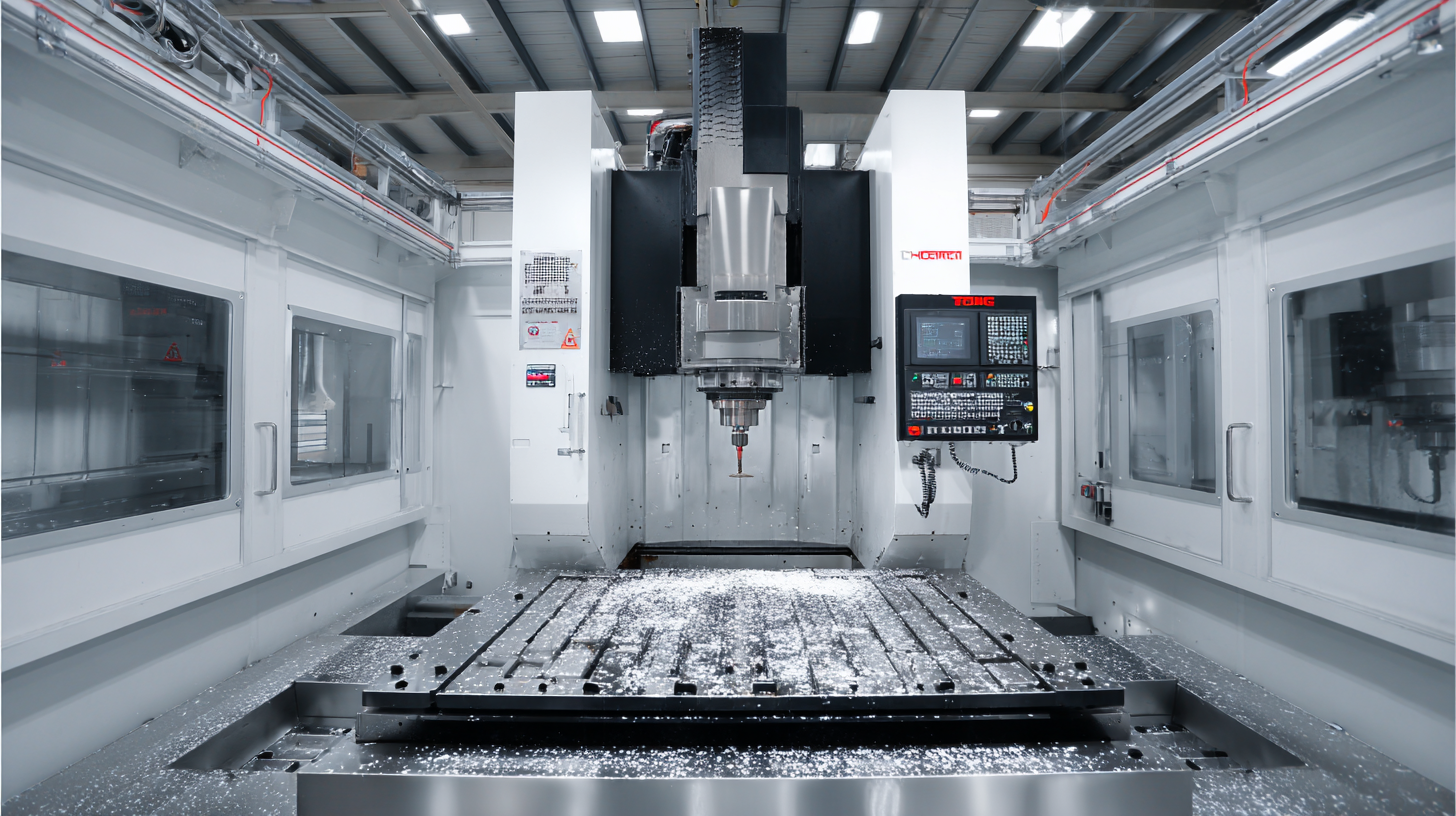

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing

In an increasingly competitive global market, the need for efficiency and precision in manufacturing has never been more critical, particularly with the rise of CNC (Computer Numerical Control) machines. According to a recent report by MarketsandMarkets, the CNC machine market is projected to reach $100 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.3%. This growth underscores the importance of optimizing production efficiency to remain competitive on the world stage. As we transition from "Made in China" to "Designed in China," the emphasis on quality is paramount in winning over international markets. Implementing cutting-edge CNC machines not only enhances precision and reduces waste but also streamlines production processes, allowing manufacturers to meet increasing demand while maintaining the high standards expected by global consumers. Thus, finding the right solutions for optimizing production efficiency becomes essential for businesses aiming to leverage the advantages offered by the best CNC machines in today's manufacturing landscape.

The Role of CNC Machines in Enhancing Global Manufacturing Efficiency

CNC machines play a pivotal role in enhancing efficiency across global manufacturing systems. The market for CNC machines is expected to experience substantial growth, projected to rise from $101.22 billion in 2025 to an astounding $195.59 billion by 2032, with a robust compound annual growth rate (CAGR) of 9.9%. This surge highlights the increasing reliance on CNC technology to streamline production processes, improve precision, and reduce waste.

In tandem with CNC machines, the bending machine market is also poised for significant expansion. By 2024, the market size is anticipated to exceed $9.5 billion, with a CAGR of 5.9% from 2025 to 2034. This growth is largely driven by the manufacturing sector's demand for high-speed automation solutions. Companies interested in optimizing their production efficiency should consider integrating advanced CNC and bending technologies to stay competitive.

**Tips:** Always assess your production needs before investing in CNC technology to ensure the best fit for your operations. Additionally, ongoing training for operators on the latest CNC advancements can enhance productivity and reduce errors in the manufacturing process. Consider scheduling regular maintenance for your machines to prolong their lifespan and ensure consistent output quality.

Key Features of Top CNC Machines for Optimal Production Performance

In the quest for optimizing production efficiency, the selection of high-quality CNC machines is paramount. These machines are equipped with advanced features that enhance accuracy, speed, and versatility across various manufacturing processes. Key characteristics of top CNC machines include high spindle speeds and torque, which significantly reduce machining time, and robust software integration that allows for seamless design-to-production workflows. Furthermore, user-friendly interfaces and real-time monitoring capabilities enable operators to streamline operations and troubleshoot issues promptly, ensuring minimal downtime.

As digital manufacturing technologies continue to evolve, the CNC machines that incorporate smart automation and IoT connectivity are becoming increasingly favored. These innovations allow for predictive maintenance and data-driven decision-making, empowering manufacturers to respond swiftly to market demands. With the U.S. CNC machines market projected to reach approximately $4 billion by 2030, it is evident that investing in these state-of-the-art machines is not only a path to heightened productivity but also a strategic move for staying competitive in the global landscape of manufacturing.

Production Efficiency Comparison of CNC Machines

Strategies for Implementing CNC Technology in Manufacturing Processes

Implementing CNC technology in manufacturing processes is crucial for enhancing production efficiency. One effective strategy is the integration of CNC machines into existing workflows. This can be achieved by first assessing the current production line to identify bottlenecks that CNC technology can address. By investing in high-precision CNC equipment tailored to specific manufacturing needs, companies can streamline operations, reduce lead times, and improve product consistency.

Another key approach is to prioritize training and support for staff to ensure they can maximize the capabilities of CNC machines. Providing employees with comprehensive training programs not only enhances their skills but also fosters a culture of innovation. Additionally, leveraging automation software can further optimize the implementation of CNC processes, allowing for real-time monitoring and adjustments that improve overall efficiency.

By combining these strategies, manufacturers can fully realize the benefits of CNC technology, leading to increased competitiveness in the global market.

Cost-Benefit Analysis of Investing in High-Quality CNC Machinery

The increasing demand for precision manufacturing in the global marketplace is driving significant growth in the CNC machine sector. According to recent projections, the global CNC machine market is expected to escalate from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 9.9%. This growth illustrates not only the rising need for high-quality manufacturing solutions but also the potential returns on investment for companies that choose to integrate advanced CNC technology into their operations.

Investing in high-quality CNC machinery can lead to substantial cost savings and efficiency improvements in production. For example, the CNC tool grinders market is anticipated to grow at a CAGR of 6.3% through 2034. This indicates that companies upgrading to superior CNC equipment can expect not only enhanced precision but also a reduction in waste and production time. By performing a thorough cost-benefit analysis, manufacturers can identify the long-term financial advantages of adopting high-quality CNC machinery, ultimately leading to optimized production processes and improved competitiveness in the global manufacturing landscape.

Real-World Case Studies: Success Stories of CNC Optimization in China

In the fast-evolving landscape of global manufacturing, optimizing production efficiency is paramount. In China, several companies have successfully implemented CNC (Computer Numerical Control) machines to streamline their operations. For instance, a leading automotive part manufacturer adopted advanced CNC technology, resulting in a 30% reduction in production time. By integrating automation with CNC systems, they minimized human error and enhanced precision, leading to significant improvements in product quality.

Another compelling case comes from a Chinese electronics firm that revamped its production line with state-of-the-art CNC machines. This integration allowed for quicker iterations of prototypes and an efficient transition from design to production. As a result, the company reported a remarkable increase in output, with a 40% boost in production capacity. These real-world case studies demonstrate how the strategic use of CNC technology not only optimizes production efficiency but also fosters innovation and competitiveness in the global market.