METROM’s

Blog

METROM’s

Blog

What is an Industrial CNC Milling Machine and How Does It Work?

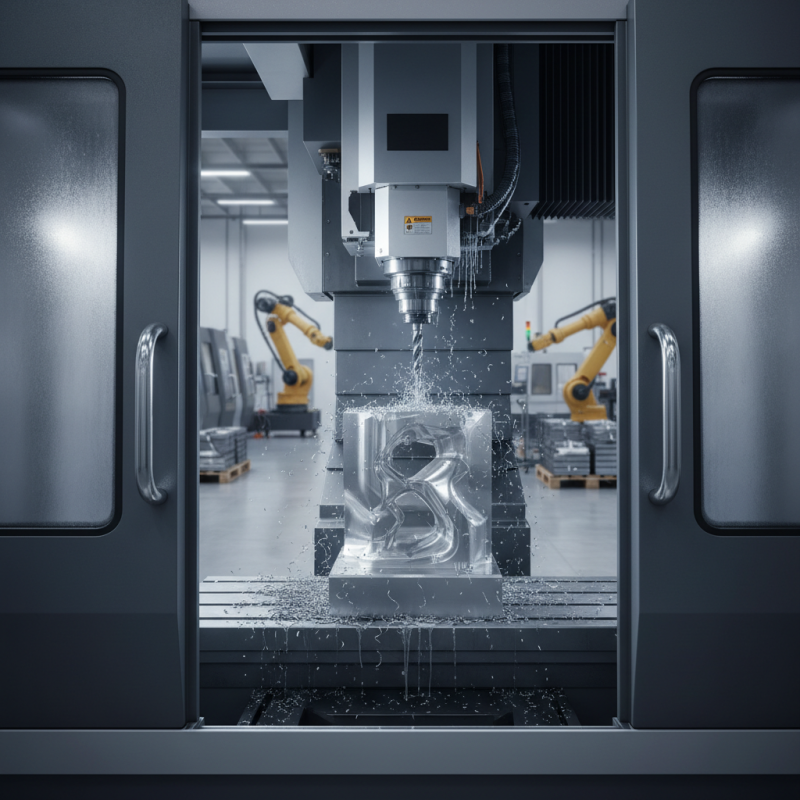

In the realm of modern manufacturing, precision and efficiency play vital roles in the production of complex components. An industrial CNC milling machine stands at the forefront of this technological evolution, offering unparalleled capabilities for shaping a wide variety of materials. This advanced machinery utilizes computer numerical control (CNC) to automate the milling process, enabling manufacturers to achieve high levels of accuracy and repeatability that manual methods simply cannot provide. By translating digital designs into physical components, industrial CNC milling machines have revolutionized how industries approach parts production, dramatically reducing lead times and minimizing waste.

As we delve deeper into the functionalities of an industrial CNC milling machine, it becomes clear how this technology enhances manufacturing processes. From intricate designs in aerospace engineering to robust components in automotive fabrication, these machines can handle an extensive range of applications. The operational principle behind these machines involves rotating cutting tools that remove material from a workpiece, allowing for intricate designs and complex shapes to be crafted with ease. In this article, we will explore the operational mechanics and advantages of industrial CNC milling machines, shedding light on how they contribute to the efficiency and effectiveness of contemporary manufacturing practices.

What is an Industrial CNC Milling Machine?

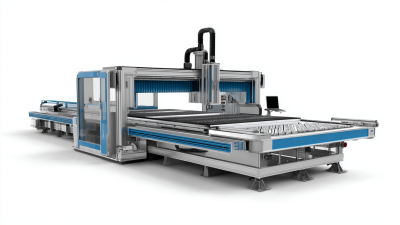

An industrial CNC milling machine is a highly advanced piece of equipment used for precision machining of various materials, including metals, plastics, and composites. CNC stands for Computer Numerical Control, which allows the machine to be controlled via a computer program. This technology enables intricate designs and shapes to be produced with remarkable accuracy, making it indispensable in modern manufacturing processes. The machine operates by removing material from a solid block using rotating cutting tools, which can be adjusted to create different profiles and finishes.

The main components of a CNC milling machine include the spindle, worktable, and control unit. The spindle holds the cutting tool and rotates it at high speeds, while the worktable secures the workpiece in place. The control unit interprets the digital design files and sends commands to move the spindle and worktable along various axes, allowing for complex 3D shapes to be machined. This automation not only enhances precision but also significantly increases production efficiency, reducing the time and labor required for manual machining processes. Overall, industrial CNC milling machines are essential for achieving high-quality results in components across numerous industries.

Industrial CNC Milling Machine Production Capacity

This chart represents the estimated production capacity of various industrial CNC milling machine types (in units per month). The data showcases how different machines cater to varying production requirements in the manufacturing sector.

Key Components of a CNC Milling Machine

CNC milling machines are vital in modern manufacturing, leveraging computerized controls to shape materials with high precision. At the core of these machines lie several key components that work together to facilitate intricate machining tasks. The most critical element is the computer numerical control (CNC) unit, which interprets G-code and translates it into movement commands for the machine. The efficiency and accuracy of a CNC milling machine directly correlate to the capabilities of its CNC unit, with advanced systems now achieving precision levels within 0.01 mm, which is pivotal in industries such as aerospace and medical equipment production.

Another essential component is the milling head, which houses the cutting tools. These heads can rotate at variable speeds, allowing for adaptability across different materials and applications. Recent reports indicate that advanced milling machines can operate with spindle speeds exceeding 20,000 RPM, significantly enhancing productivity and surface finish quality. Additionally, the worktable, which holds the material in place, is designed to be rigid and precise, often featuring T-slots for versatility in setup. Many modern tables include automatic clamping systems, improving safety and efficiency by minimizing manual interventions. Overall, the harmonious interaction of these components enables CNC milling machines to achieve high productivity levels, with current industry data suggesting that their implementation can increase efficiency by up to 30% in comparison to traditional milling methods.

How CNC Milling Machines Operate: A Step-by-Step Guide

CNC milling machines operate through a precise and automated process that involves several critical stages. Initially, the machine's control unit interprets a design file, often created in CAD software, converting it into G-code—a language that guides the machine's movements. The detailed instructions dictate how the cutter will move along the X, Y, and Z axes, allowing for intricate designs. According to industry data, CNC milling technology can achieve tolerances as tight as ±0.005 inches, which is crucial for applications that require high precision.

During operation, the machine begins by securing the workpiece, which can be made from various materials such as metals, plastics, or composites. The spindle, which holds the cutting tool, then rotates at high speeds, enabling efficient material removal. As the machine executes the programmed path, the cutter engages with the material, shaping it according to the specified design. This process not only reduces human error but also significantly enhances production speed, making CNC milling a preferred method in sectors such as aerospace and automotive manufacturing.

Tips: To maximize efficiency with CNC milling machines, ensure that tooling conditions are optimal by regularly checking the sharpness of the tools and maintaining proper coolant levels. Additionally, consider conducting regular maintenance checks to avoid unexpected downtimes that can impact production schedules. Implementing these practices can lead to a longer tool life and improved machine performance, as indicated by recent machinery reliability studies.

Applications and Industries Utilizing CNC Milling Machines

CNC milling machines play a pivotal role across various industries, thanks to their precision and versatility. In aerospace, for instance, components such as turbine blades and structural parts are manufactured using these machines to meet stringent tolerances and weight requirements. The ability to produce complex geometries efficiently allows aerospace manufacturers to maintain high safety standards while optimizing performance. Additionally, automotive industries utilize CNC milling for fabricating parts like engine blocks and chassis components, where precise machining is essential for ensuring durability and functionality.

The medical sector also benefits significantly from CNC milling technology. Surgical instruments, implants, and prosthetics are crafted with utmost accuracy to guarantee safety and effectiveness for patients. The customization capabilities of CNC milling enable manufacturers to create tailored solutions that meet individual patient needs, enhancing the overall quality of care. Other areas such as electronics, where components must fit perfectly within devices, and consumer goods manufacturing, which requires high-volume production of small parts, further highlight the extensive applications of CNC milling machines in modern industry. This technology continues to evolve, driving innovation and efficiency across a plethora of sectors.

Benefits and Advantages of Using CNC Milling Technology

CNC milling technology offers numerous benefits that make it a preferred choice in various industrial applications. One of the primary advantages is its ability to produce complex geometries with high precision and repeatability. Unlike traditional machining methods, CNC milling machines can easily accommodate intricate designs and tight tolerances, significantly enhancing the quality of the finished product. This capability reduces the need for multiple setups, streamlining the manufacturing process and saving both time and costs.

Another significant benefit is the automation aspect of CNC milling. The machines are programmed to carry out precise movements, which minimizes human error and increases efficiency. This automation allows operators to focus on monitoring and maintaining the machines rather than performing repetitive tasks, ultimately improving productivity in the workshop. Additionally, CNC milling machines can operate continuously for extended periods, further maximizing output and reducing labor costs.

Tips: When selecting a CNC milling machine for your operations, consider factors like the materials you’ll be working with and the size of the components you need to produce. Also, investing in training for your operators can enhance efficiency and machine utilization, leading to better production outcomes. Engaging with experienced professionals can help streamline the integration of CNC technology into your existing processes.

Related Posts

-

The Future of Precision Manufacturing: Advancements in CNC Milling Machines

-

2025 Top 5 Precision CNC Milling Machines for Enhanced Manufacturing Efficiency

-

The Ultimate Guide to CNC Machine Tools Understanding Trends Technologies and Market Dynamics

-

Revolutionizing Manufacturing: The Essential Guide to CNC Machine Industrial Innovations

-

A Comprehensive Comparison of the Top Industrial CNC Machines for Global Buyers

-

Solutions for Optimizing Production Efficiency with the Best CNC Machines in Global Manufacturing