METROM’s

Blog

METROM’s

Blog

Why 3D Printing Machines Are Transforming Modern Manufacturing and Design

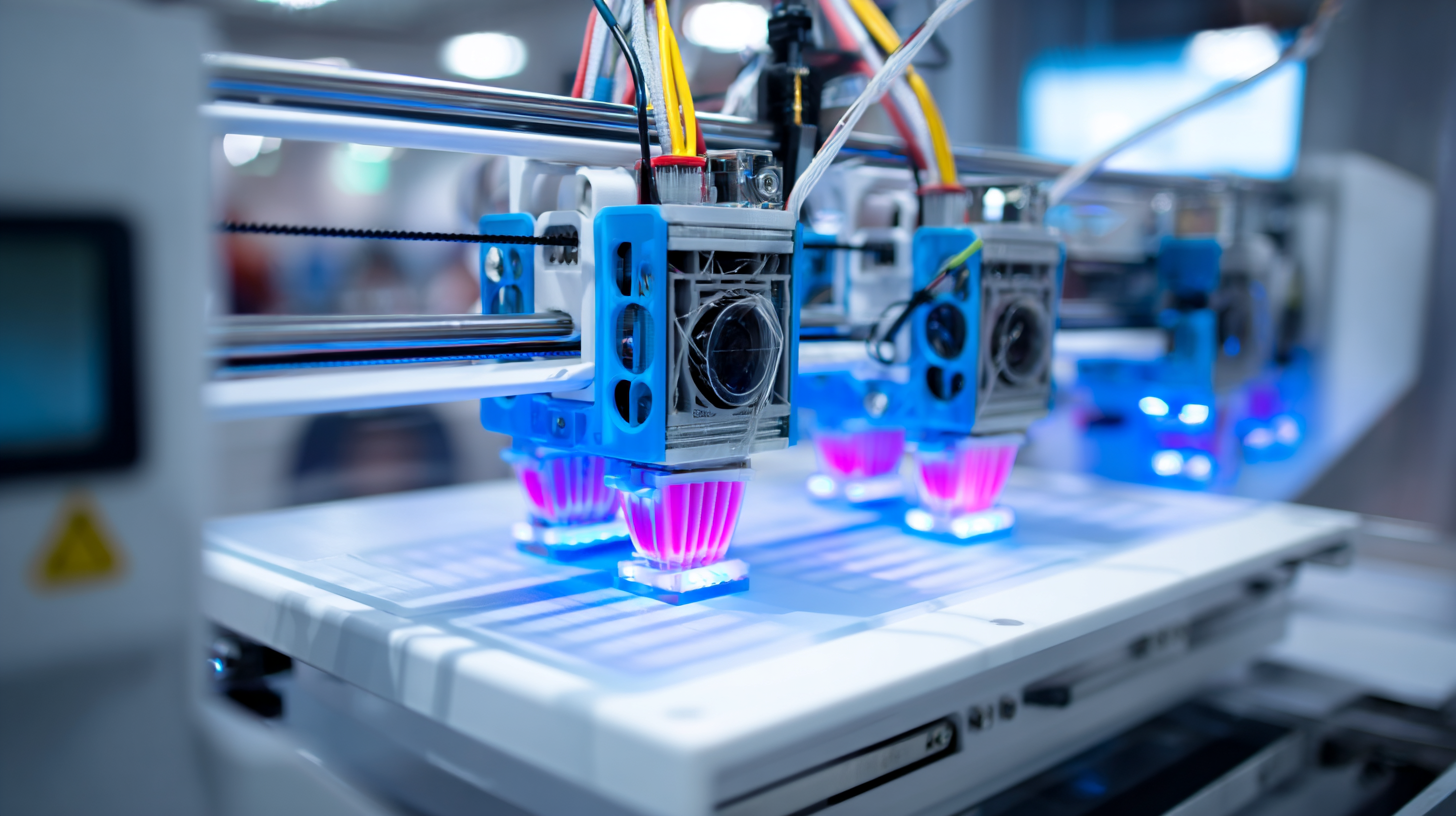

In recent years, the emergence of 3D printing machines has revolutionized the landscape of modern manufacturing and design. These innovative devices have transcended traditional production methods, enabling designers and engineers to create complex structures and unique products with unprecedented levels of customization and efficiency. As industries strive to adapt to rapidly changing consumer preferences and technological advancements, 3D printing machines have become essential tools that offer significant advantages in terms of cost-effectiveness, speed, and sustainability.

The ability to rapidly prototype and iterate designs through 3D printing machines allows for a more agile manufacturing process. This has significant implications for various sectors, including aerospace, automotive, healthcare, and consumer goods. The shift towards additive manufacturing not only streamlines production but also opens up new avenues for material usage and product innovations that were previously unattainable. As businesses leverage these advanced technologies, they redefine their capabilities and remain competitive in an increasingly globalized market.

Ultimately, the transformative impact of 3D printing machines extends beyond mere operational efficiencies; it fosters a culture of innovation and creativity. Companies are now able to push the boundaries of design, experimenting with complex geometries and personalized products that directly cater to individual consumer needs. In exploring the various aspects of 3D printing, this discussion will highlight its pivotal role in shaping the future of manufacturing and design.

The Impact of 3D Printing on Traditional Manufacturing Processes

The rise of 3D printing technology is significantly redefining traditional manufacturing processes, particularly in the realm of medical device innovation. This transformative approach enables manufacturers to create highly personalized devices tailored to the unique needs of individual patients. A report from Wohlers Associates indicates that the global 3D printing market is projected to reach $35.6 billion by 2024, highlighting its critical role in driving efficiencies and customizations in medical manufacturing. Companies leveraging 3D printing can reduce development times substantially, often cutting them in half compared to conventional methods, enabling faster go-to-market strategies.

Furthermore, the integration of artificial intelligence (AI) within 3D printing is poised to elevate the industry even further. Experts predict that AI applications in additive manufacturing can enhance design optimization, predictive maintenance, and quality control, creating a more streamlined and efficient production cycle. As noted in a recent survey, approximately 70% of additive manufacturing professionals believe that AI will play a crucial role in the future of production, helping businesses not only to innovate but also to maintain competitiveness in a rapidly evolving marketplace. With thousands of startups entering this space, it is clear that the implications of 3D printing and AI are vast, setting the stage for a new era of manufacturing excellence.

How 3D Printing Facilitates Rapid Prototyping and Design Iteration

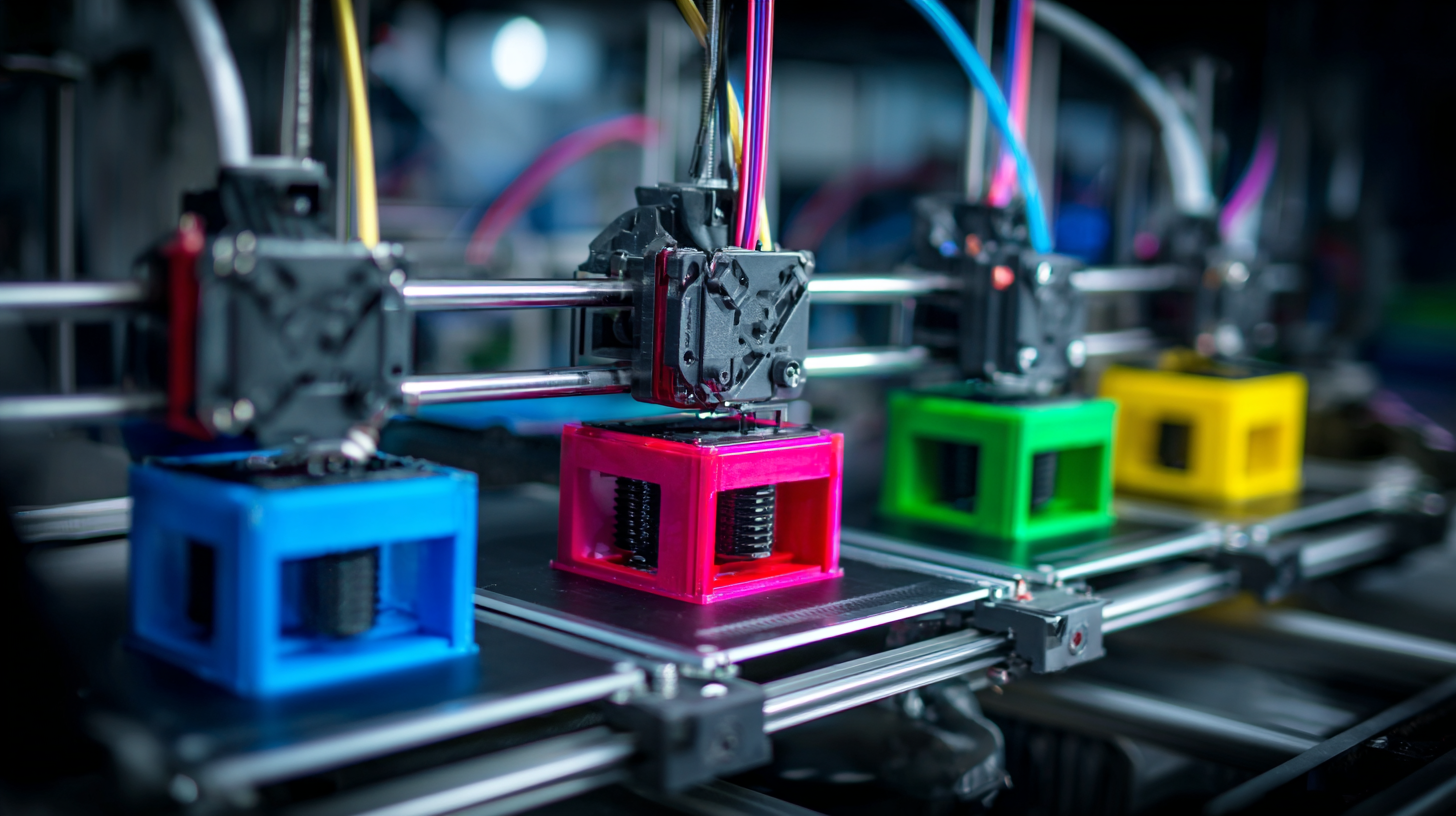

The integration of 3D printing technology into modern manufacturing processes is fundamentally reshaping how industries approach prototyping and design iteration. Companies are increasingly investing in 3D printing as a tool for rapid prototyping, which allows for the swift creation of prototypes that can be tested and refined in real-time. This capability not only accelerates product development cycles but also enables businesses to bring products to market more quickly. For instance, the medical industry has experienced significant reductions in time-to-market, with 3D printing facilitating the expedited design and testing of medical devices. Reports indicate that the prototyping phase, which once took months, can now be condensed to weeks or even days, enhancing overall efficiency.

Moreover, the flexibility offered by 3D printing allows for intricate designs and customizations that were previously inconceivable with traditional manufacturing methods. High-performance sectors such as motorsport have particularly benefited, where low-volume production saves costs without compromising on quality or innovation. An analysis of industry data shows that companies utilizing rapid prototyping techniques can achieve up to a 40% reduction in development time. This continuous improvement and iteration lead to better final products, showcasing how critical 3D printing has become in enabling businesses to meet consumer demands effectively and stay competitive in fast-paced markets.

3D Printing Impact on Modern Manufacturing

This bar chart compares key metrics between traditional manufacturing and 3D printing. The data highlights significant advantages of 3D printing in terms of reduced prototyping time and costs, as well as lower material waste, allowing for faster design iterations.

Cost-Effective Production: The Economic Advantage of 3D Printing

3D printing technology has emerged as a cost-effective solution that is transforming modern manufacturing and design. Various processes, such as FDM, SLA, and SLS, enable the production of complex geometries using materials ranging from metals to polymers. This adaptability significantly reduces production costs, making it accessible for small and medium enterprises (SMEs). By lowering entry barriers, 3D printing allows these businesses to innovate rapidly and compete effectively in a global market.

Moreover, advancements in 3D printing continue to identify strategies for further cost reduction. For instance, hybrid approaches in metal printing are being developed to enhance efficiency and sustainability. The application of 3D printing is not limited to traditional manufacturing; innovative uses such as 3D-printed buildings address critical housing shortages while minimizing environmental impact. As the technology matures, it paves the way for economic growth across diverse sectors, facilitating a new era of manufacturing that is not only more affordable but also more sustainable and efficient.

Customization and Personalization: Meeting Unique Consumer Demands with 3D Printing

The rise of 3D printing technology is revolutionizing the manufacturing and design landscape by fostering unprecedented levels of customization and personalization. Unlike traditional methods that often rely on mass production, 3D printing allows manufacturers to create tailored products that meet the specific needs and preferences of individual consumers. This flexibility not only enhances product uniqueness but also enables brands to cater to niche markets without the overhead costs associated with conventional manufacturing processes.

Furthermore, 3D printing empowers consumers to be part of the design process. With user-friendly software, individuals can modify existing models or design their own products from scratch. This capability encourages a participatory approach to product development, where the end-user can embody their personal style and functional requirements. As a result, businesses that incorporate 3D printing into their operations can quickly respond to fluctuating consumer demands, creating a competitive edge in a saturated marketplace.

The fusion of creativity and advanced technology offers limitless possibilities for customized solutions, reshaping the consumer experience.

Sustainability in Manufacturing: The Eco-Friendly Benefits of 3D Printing Technology

3D printing technology is redefining sustainability in manufacturing by minimizing waste and energy consumption. Traditional manufacturing processes often generate significant amounts of scrap material, but additive manufacturing—where products are built layer by layer—allows for precise production that uses only the necessary amount of material. This reduction in excess not only cuts costs but also means less waste is sent to landfills, contributing to a more sustainable manufacturing cycle.

Moreover, 3D printing enables manufacturers to utilize eco-friendly materials, including biodegradable plastics and recycled components. As the technology advances, companies are increasingly able to produce items that are not only functional but also environmentally responsible. By adopting such practices, businesses can reduce their carbon footprint, making 3D printing not just a means to innovate design but also a catalyst for environmental stewardship in the industry. Through these efforts, 3D printing stands out as a transformative force that aligns technology with sustainable practices in modern manufacturing.

Related Posts

-

What Makes the Best CNC Machine 3D Printer Stand Out in Global Markets

-

Challenges Faced When Choosing the Best CNC Milling Machine for Your Business

-

5 Incredible Reasons Why 5 Axis Milling Machines Are Revolutionizing Manufacturing Efficiency

-

Exploring the Best CNC Machines and Their Alternatives for Your Business Needs

-

Strategies for Sourcing the Best Milling Machine Tools in the Market Analysis of 2025

-

Unleashing Global Excellence in Manufacturing with the Best 3D CNC Machines from China